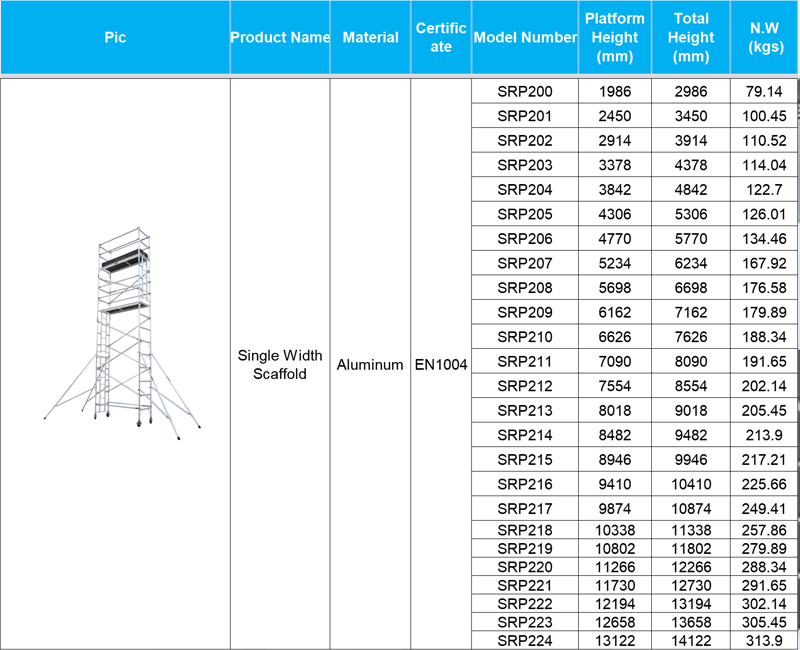

Single Width Aluminum Scaffolding Tower

tags: Double width scaffolding, Wide scaffolding, Aluminum scaffolding

Product Description

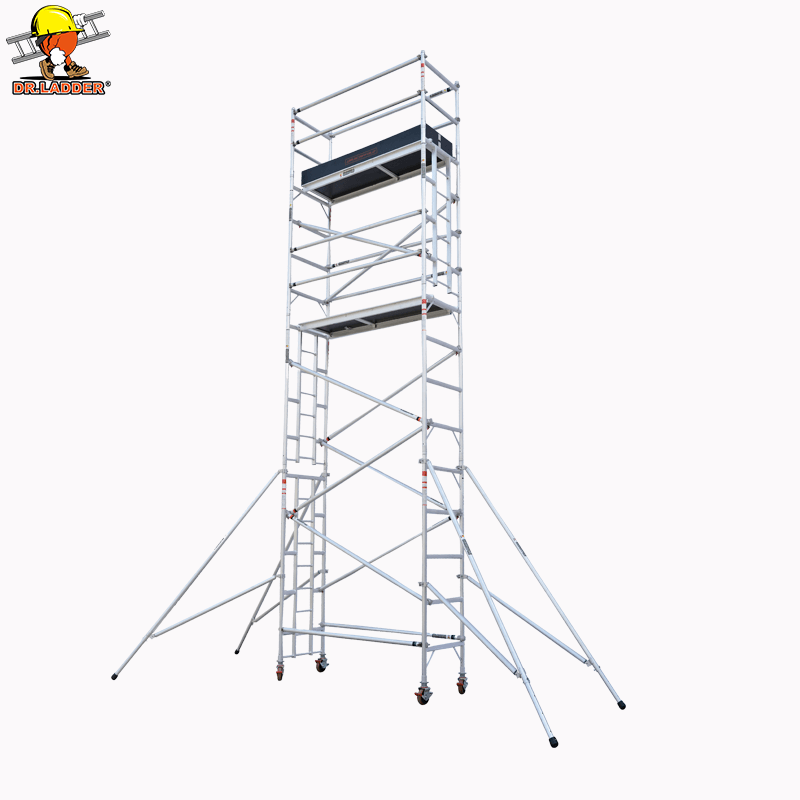

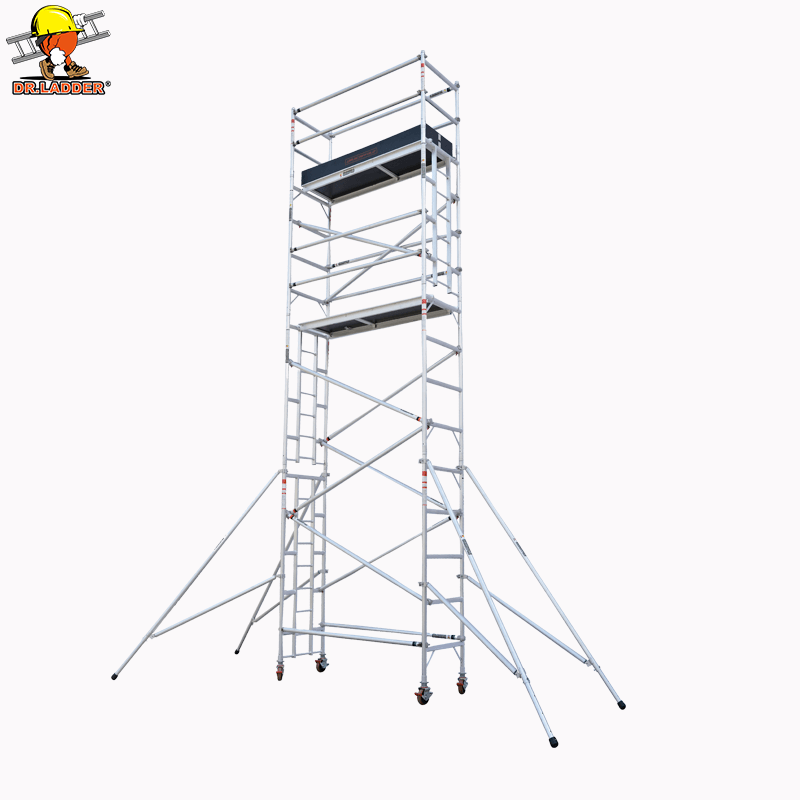

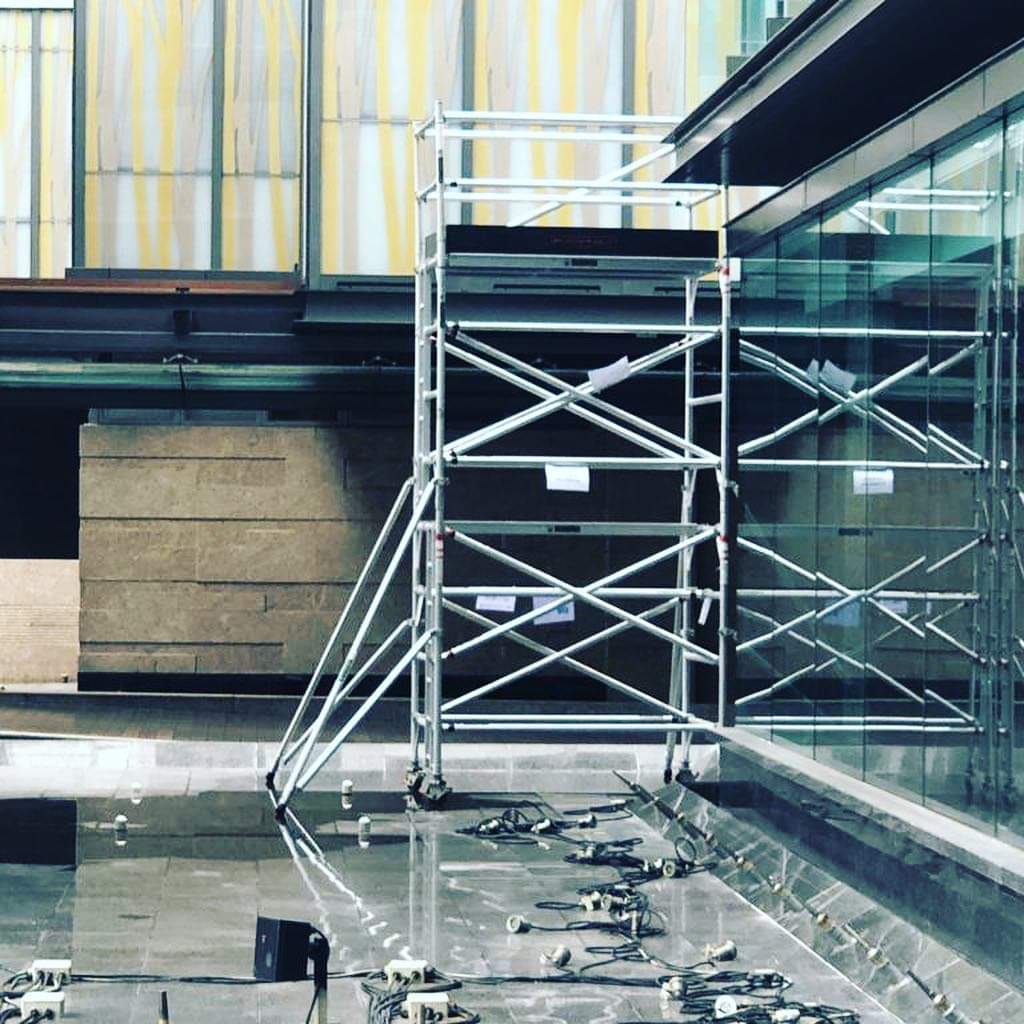

Single Width Narrow Mobile Aluminum Scaffolding Tower

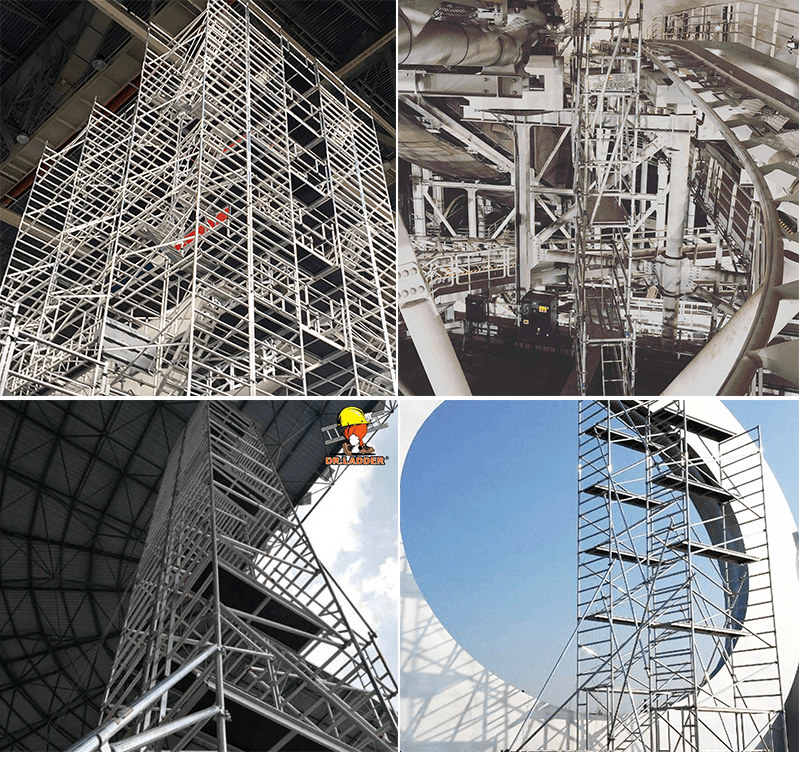

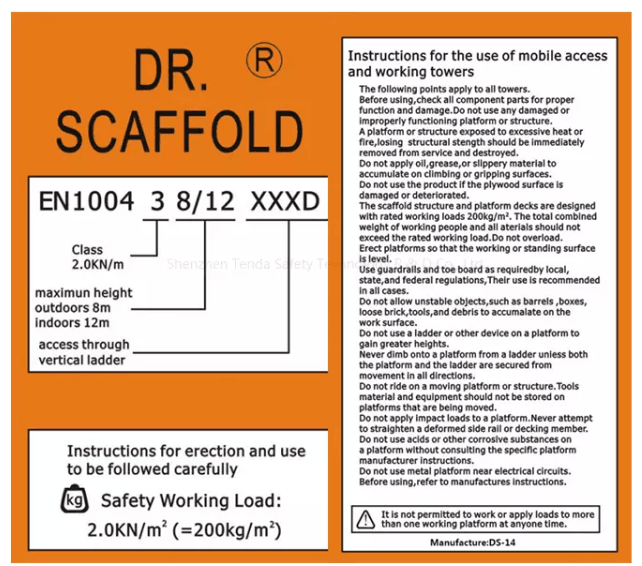

The Single Width Narrow Aluminum Scaffolding Tower is ideal for the industrial or the professional use with a load capacity of 200kg per square meter. DR.SCAFFOLD DRP100 Series are wide width scaffold, quick and simple to use. The 6061-T6 aluminum alloy and professional design structure make the scaffold more stable and safe. Additional scaffold sections and components can be added to the tower for maximum flexibility. The scaffolding approved to the EN1004 standard.

Overview

| Model No. | Style | Platform Height | Load Capacity | Max. Safe Working Height | Reach Height | Guadrail Height | Certificate |

| SRP200 Series | Narrow Scaffold | 1986~13122mm | 200kg/Square meter | 1.986m~13.122m | 3.8~15m | 1000mm | EN1004 |

Features

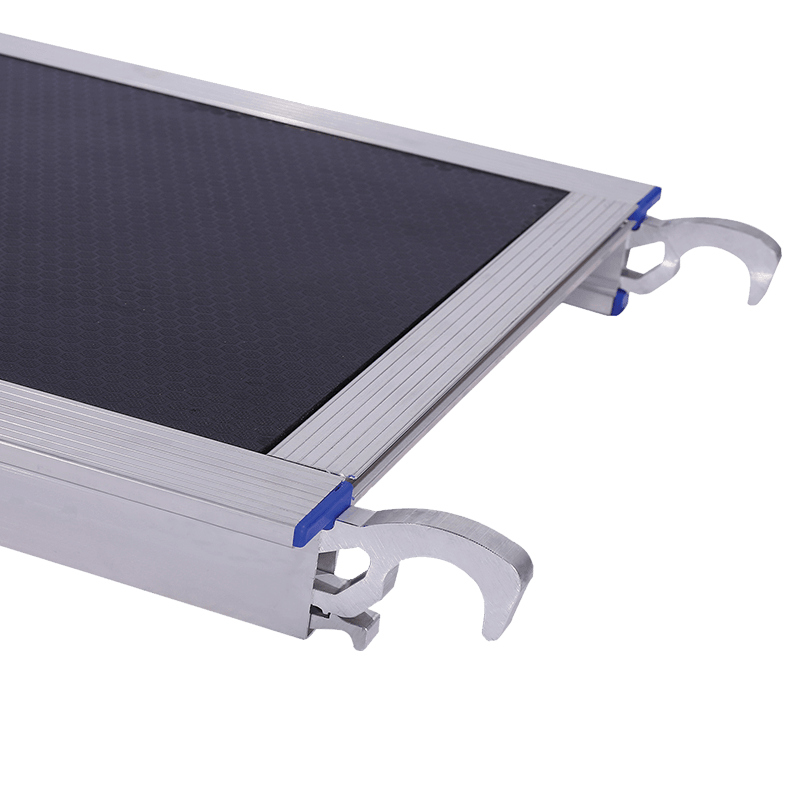

The premium aluminium modular access tower system featuring easy climb rung spacing.

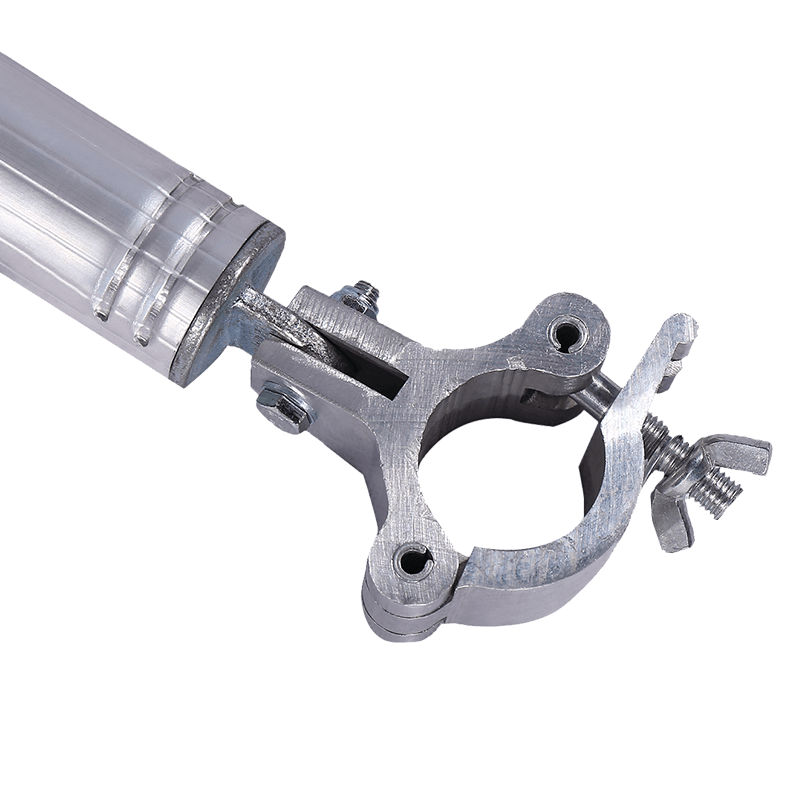

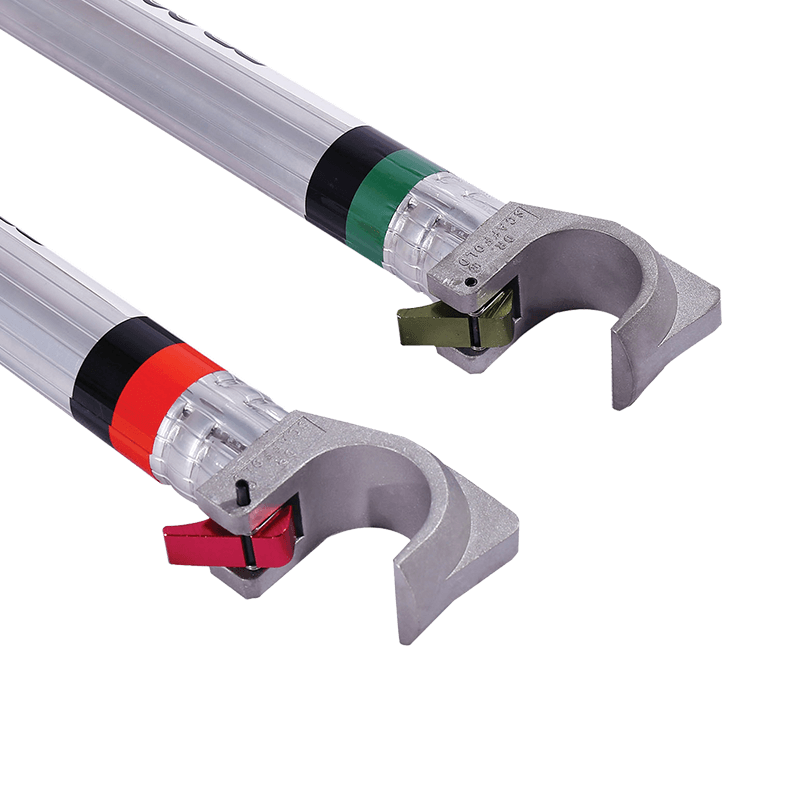

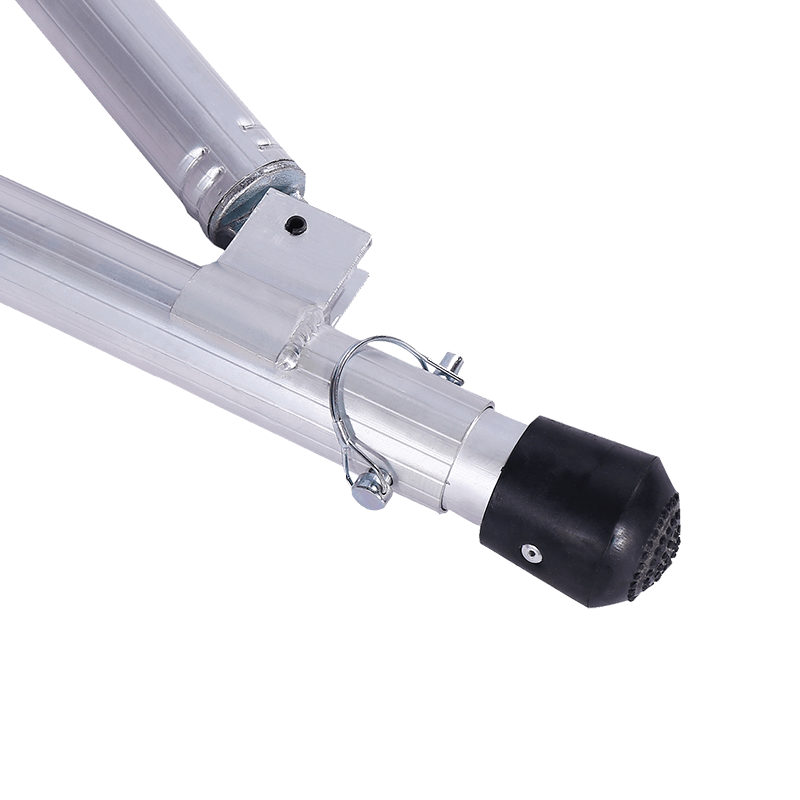

Protected locking pins prevent accidental release.

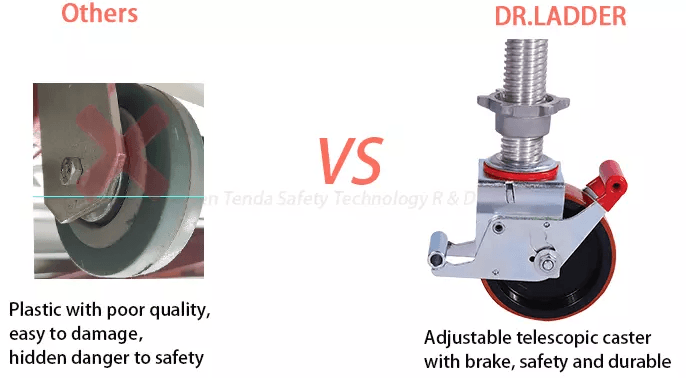

Locking casters swivel for convenient 360-degree mobility.

No tools required for quick setup and tear down.

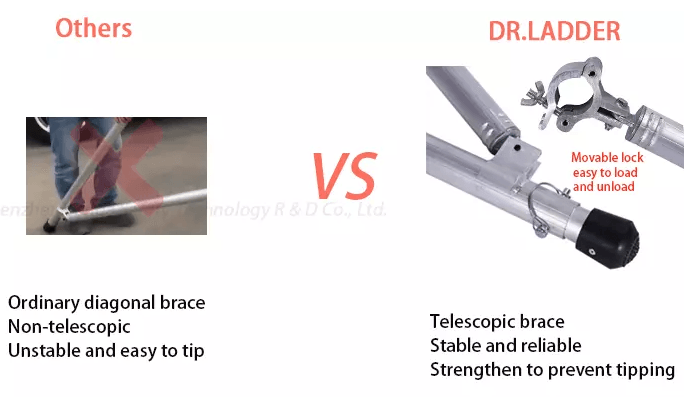

Heavy duty bracing for enhanced bracing strength to protect rail against damage.

Ideal for schools, hospitals and building maintenance.

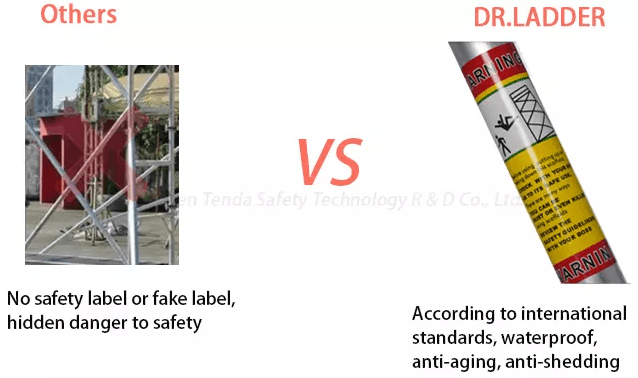

High quality safety stickers - waterproof, anti-oxidation, more than 20 years lifetime.

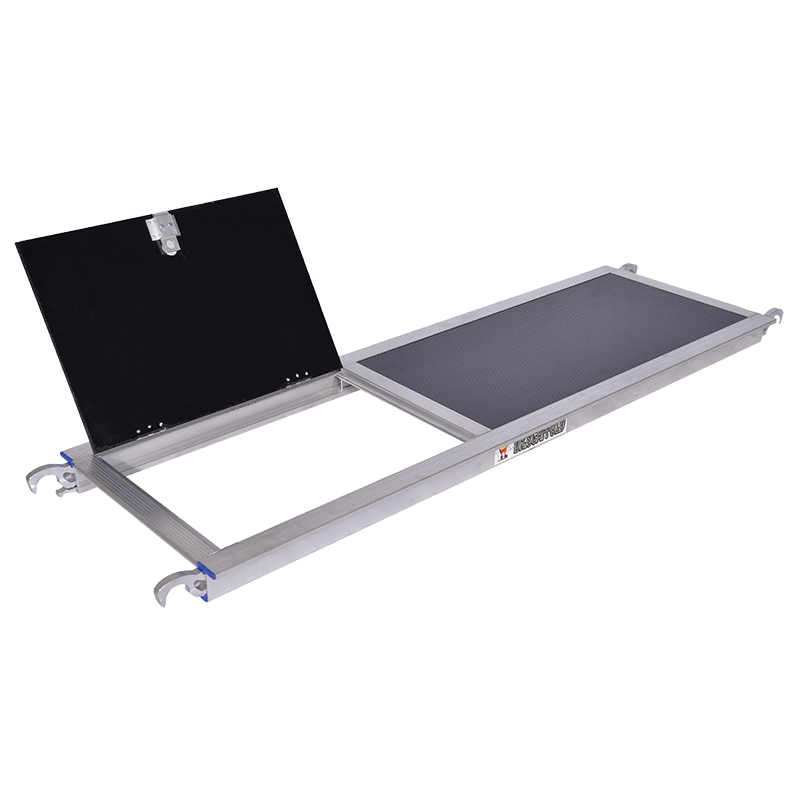

Including guardrails, toeboards, and telescopic stabilizer, extension caster etc.

Platform height adjustable in 16 inch/0.4m increments for unique working heights and uneven surfaces.

Reviews from customers

Easy to assemble ![]()

Easy to use ![]()

Maneuverability ![]()

Sturdiness ![]()

Durability ![]()

Questions

1. what materials are this scaffolding made of?

6061-T6 aluminum alloy. very stable and sturdy.

2. Approved to international standard?

Sure. All of our scaffolding are strictly tested and passed EN1004 standard.

the load capactity is 200kg/Sq.m.

3. Where can I buy it?

You can contact us directly: service@tenda-safety.com +86 18665016702

4. How long will you delivery after I purchase the ladder?

samples for 2-3 days, mass production for 30-45 days.

5. Can I buy samples first?

Yes,sample order is available for quality checking and market testing.

6. Are you trading company or factory?

We are the manufacturer of ladders & scaffolding.

7. Can you do our logo or brand on the products?

No problem, we can do it for free. OEM and ODM are available.

8. How does your factory do regarding quality control?

Each process is strictly tested by international standard from purchasing the raw materials to production. we have our own test laboratory. All designs and materials are strictly tested and reach the national level including EN131, ANSI, AS/NZS, EN1004 standard.

10. Can I mix different type in one container?

Yes, different models can be mixed in one container, you can chose different model to mixed in one container.

11. What's your packing methods?

Plastic bag and carton box

What you don't know can hurt you till when it happens like:

Are the ladders you purchased really safe?

Let's see the truth.

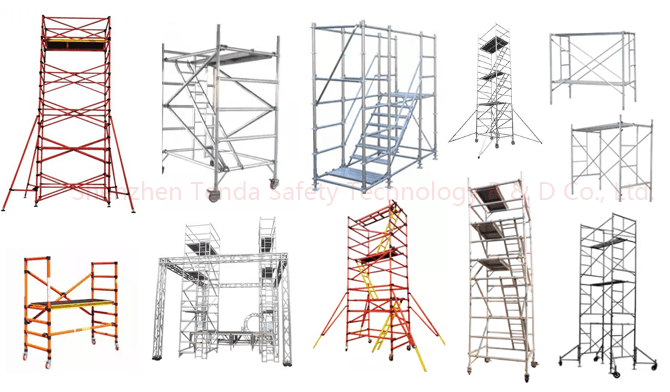

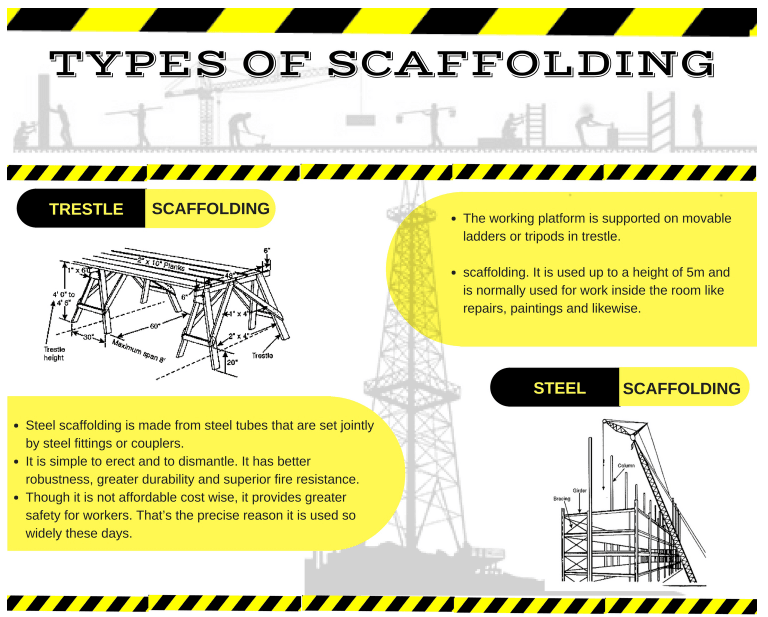

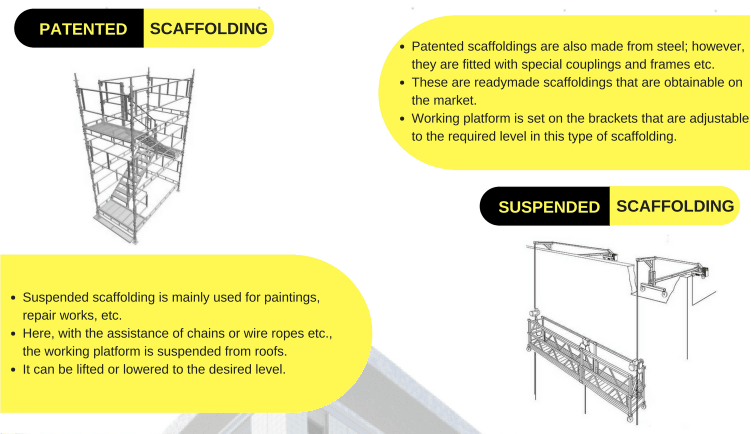

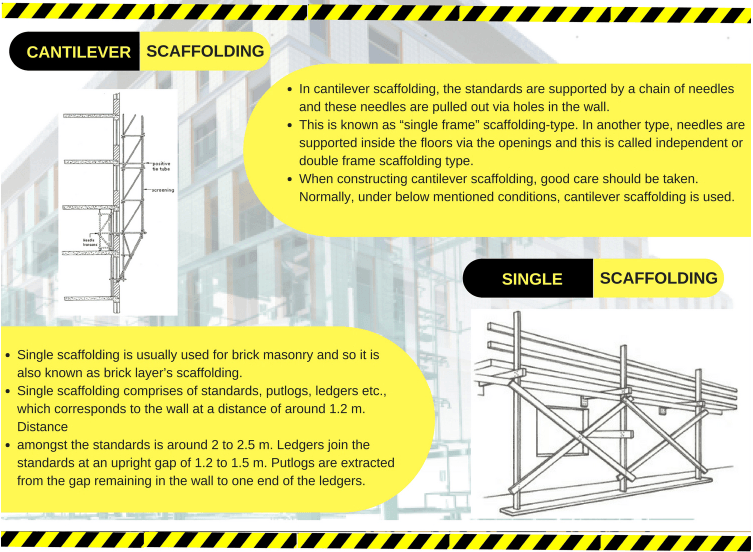

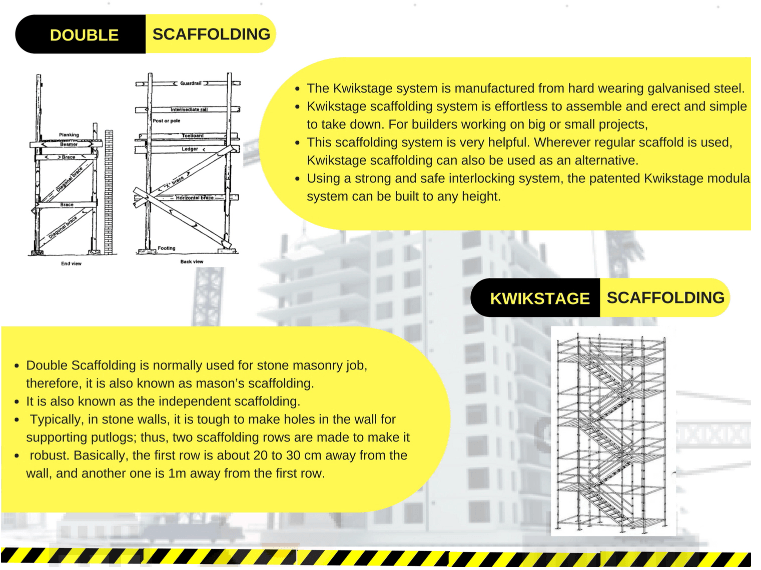

You may have purchased a variety of scaffolding, like these:

So many! But how to choose the right scaffolding?

Four key elements of scaffolding selection are: Style, Height and Capacity, Materials, and Unique Product Solutions.

1. Selecting the Right Scaffold Type

2. Selecting the Height and Capacity

EN1004 Standard:

Ensure that the stabilizers/outriggers are in position to maintain a height to base ratio of 3:1 if used extemally, or 3.5:1 if

used internally.

The table below shows at what height OSHA's restraint provision (§1926.451(c)(1)) would require the indicated scaffold model, when used with outriggers as described above, to be restrained (by guying, tying, bracing, or equivalent means) to prevent tipping.

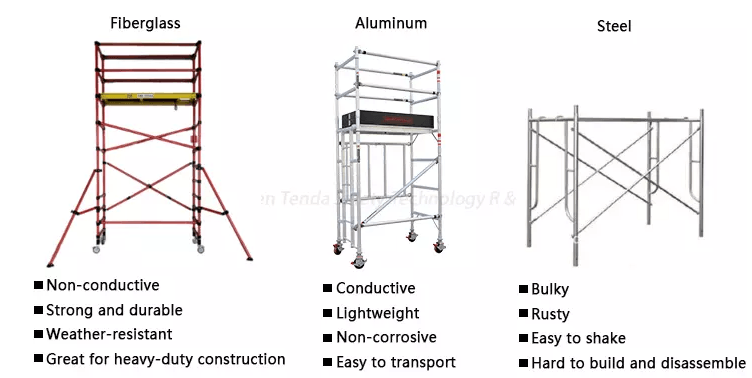

3. Selecting the Right Material

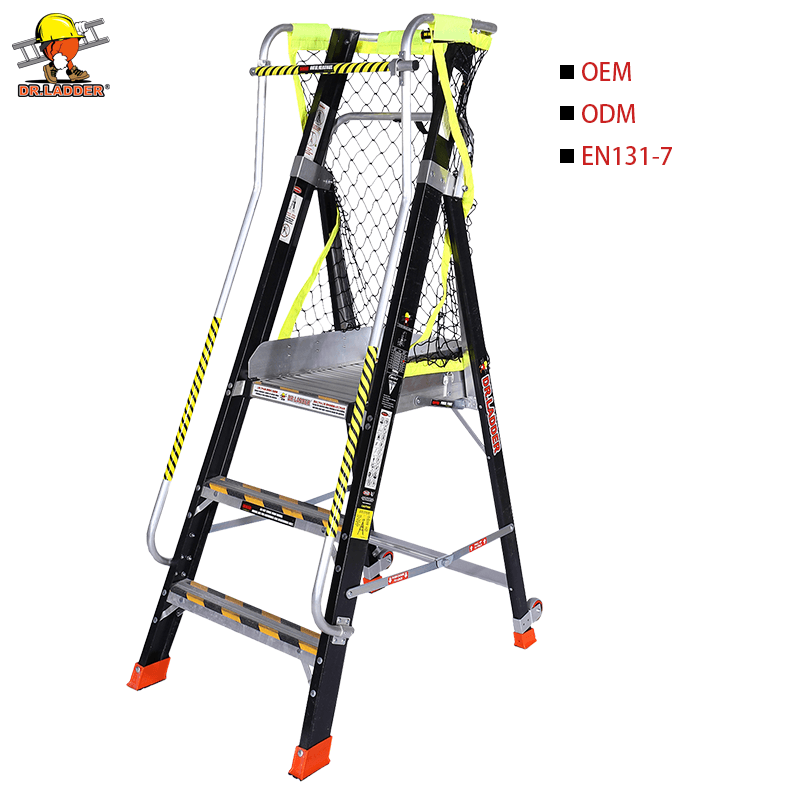

It's important to consider what material your scaffold is made from. Tenda offers scaffold made from both fiberglass and aluminum. Each material offers unique benefits suited to particular conditions, applications, or preferences.

4. Selecting the Unique Product Solutions.

Tenda offers a large selection of innovative designs to tackle any job.

According to the U.S. Consumer Product Safety Commission, each year finds about 165,000 scaffold-related injuries occurring. Many are preventable with some common sense and following basic scaffold safety.

At DR.SCAFFOLD, all of our products are designed and constructed to meet or exceed applicable standards and requirements of EN, ANSI/SSFI, OSHA, AS/NZS, CAN/CSA.

Please

Inspection before each use

1. Inspect thoroughly for missing or damaged components. Never use a damaged scaffold and never make temporary repairs.

2. Inspect thoroughly for loose fasteners. Make sure all working parts are in good working order (lubricate if necessary).

3. Destroy scaffold if damaged, worn, or exposed to fire or chemicals.

Safety Notes

1. Ensure scaffold is erected in accordance with the manufacturers assembly instruction leaflet.

2. Ensure the scaffold is erected on a solld base. Use soleboards where necessary.

3. When erecting and using, ensure the scaffold is level and in contact with the ground by adjusting the wheels/baseplates and the stabilizers/outriggers.

4. When erecting, brace the scaffold in accordance with the manufacturers assembly instruction leaflet.

5. Ensure that the stabilizers/outriggers are in position to maintain a height to base ratio of 3:1 if used extemally, or 3.5:1 if used internally(EN1004).

6. Fit toe-boards and guardrails to all platforms over 2 m high.

7. Tie in or guy down scaffolds whenever possible and all scaffolds over 10 m in height.

8. Ensure the scaffold is secure when left unattended.

9. Before use ensure the scaffold is complete and that the wheels are locked.

10. Always climb scaffolds from the inside via ladders or stairways. Do not extend the height of the platform by the use of ladders. boxes or other devices.

11. Before moving the scaffold ensures that it is clear of obstructions, overhead and at ground level, and that no person or materials are upon it.

12. To move the scaffold only apply force by pushing at or near the base.

13. Do note that substances such as hydrochloric (muriatic) acid and potash are highly corrosive to aluminium and can seriously affect the strength of the equipment.

14. Beware of strong wind conditions, especially between buildings. Always tie-in the tower to a rigid structure in exposed conditions, e.g. When the wind force exceeds Beaufort Scale 4.

15. Avoid subjecting the tower to horizontal forces. Horizontal forces must not exceed 20 Kg on free-standing towers. Take care when a drill is being used. Tie in if required.

16. Damaged or incorrect components shall not be used.

17. Stabilisers or outriggers and ballast shall always be fitted when specified.

18. Mobile Access Towers are not designed to lifted or suspended.

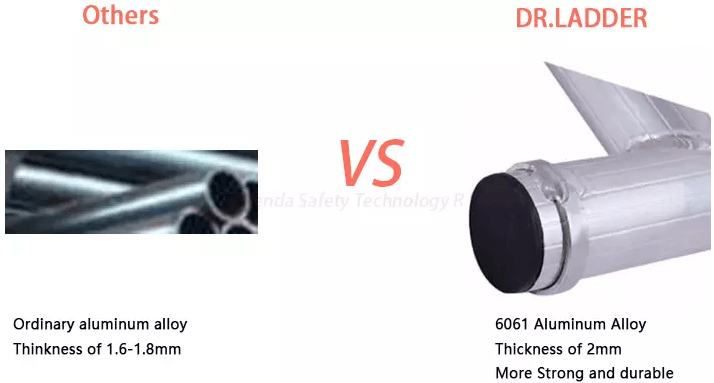

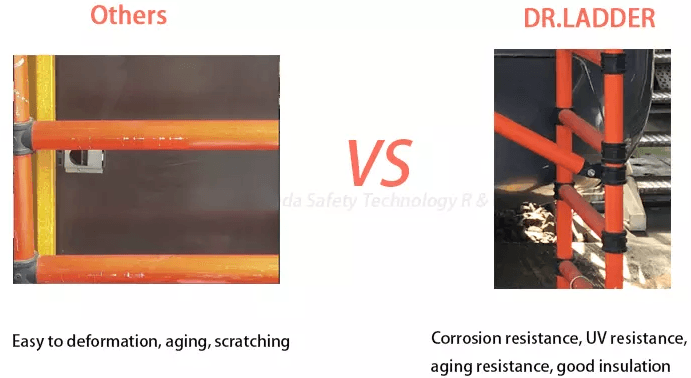

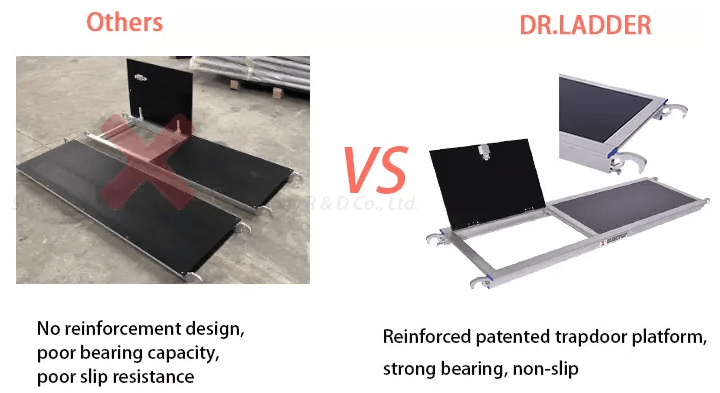

But how to distinguish between good and bad scaffold?

1. Comparing material

Strike the fiberglass by hand to check the hardness, whether it is deformed, whether the surface is smooth, and whether the color is uniform.

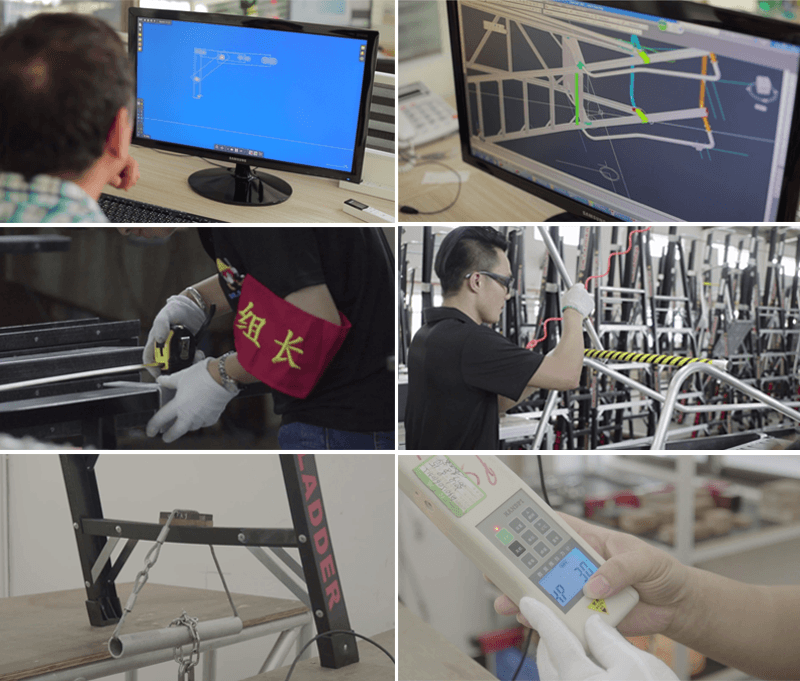

2. Comparing Product Structure

3. Checking Certificates and Test Reports

We have our own testing laboratory, material and design are based on international standards.

Company Profile

Shenzhen Tenda Safety Technology R & D Co., Ltd. is a high-tech integrated company in research and development, production, sales and service. We are specialized in design and development of ladders and scaffold tower for many years of industry experience.As an industry benchmark and leader, we are dedicated to aluminum / fiberglass platform ladders, cage ladders, handrail ladders, leaning ladder, straight climbing ladders, extension ladder, multi-purpose ladder, aluminum scaffolding tower, ring lock scaffolding, work platform and other safety construction equipment. All of our products are strictly tested and have passed American ANSI, European EN131, Australian AS quality testing certification.Professional technical personnel, precise production equipment, super production capacity, which are all the strengths that Tenda possesses to make the best high-altitude operation and safety working equipment for customers.OEM and ODM are available. We enthusiastically welcome customers from all over the world.

Why choose DR.SCAFFOLD?

1. It uses 6061 high-strength alloy aluminum, and it's strength and force have passed the EN1004 standard test.

2. Dr.scaffold's products are featured with laser mark to guard against counterfeiting.

3. Dr.scaffold's products have applied for a patent for appearance, all rights reserved.

4. We guarantee permanent maintenance for our products.

5. Ingenious design, meticulous testing, to create the perfect safety ladder. Dr. Ladder makes every user, Safety Up - Safety Down - Safety Home