What types for aluminum scaffolding systems

There are many models of aluminum alloy, and the models are different, which means that the forging process is different, and it is suitable for creating different products. For example, 6061 aluminum plate is also used to indicate that it is a mold aluminum plate.

The thickness of the 6061-T6 aluminum plate can be processed from 0.3 to 600 mm, and the post-treatment can be used as quenching treatment, pre-stretching, decorative plate, etc. The 6061 aluminum plate manufacturing products are mainly used in various industrial structural parts with a certain strength, weldability, and corrosion resistance. Type 6061 aluminum plate is also widely used in the field of automobile manufacturing. It is a good material for the processing of car body parts. It is also used for the processing of tank car bodies. At the same time, the aluminum plate has the advantages of corrosion resistance, good welding performance, and easy processing and forming in the construction field. Compared with the 5052 phase, the magnesium content in the 5 system is relatively low,

The 5052 punch is inserted into the draft of the end face and side (rib) strip of aluminum alloy forgings. Therefore, the web part of the die forging can actually produce a "stretching" effect. Therefore, the present invention method is to adjust rather than eliminate the overall stress level of the parts, to release the residual stress of certain parts of the aluminum alloy die forgings, and increase the residual stress of other parts. In addition, due to the large residual stress of aluminum alloy die forging, excessive compression deformation will cause cold deformation hardening, cracking, and fracture and too small deformation will make the stress release effect poor. The limitation of this method is that it is difficult to operate in actual operation. Accurately control the amount of compression deformation.

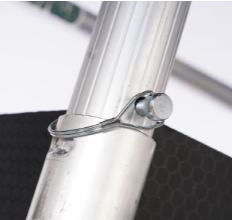

Therefore, the aluminum alloy scaffold of DR.LADDER uses 6061 aluminum alloy as the material. The aluminum alloy tube has a wall thickness of 2.0mm, is light in weight and has a large load capacity, and adopts a triangular fixed structure, which is stable and safe as a whole. We have tested it for a long time and it is most cost-effective to use 6061 aluminum with a wall thickness of 2.00mm, which can be used to build tower scaffolding with a height of 2-40 meters. In addition to tower scaffolding, 6061 can also be used as support plate scaffolding. It has a building block design. The overhanging type can resist a level 10 typhoon without shaking. The floor-standing wind resistance level is higher.